Why Concrete Needs Protection

Important Facts from the Scientific Journal Coatings

Concrete is widely considered one of the toughest products available for use in construction. Easily formed into a variety of shapes, yet solid after it is completely cured, this modern version of an ancient building material is critical to the world economy. According to the March 2025* issue of the Swiss journal Coatings, concrete is “a core material in modern construction and infrastructure, [and] is used globally at a rate of approximately 250 million tons per year, making it one of the most cost-effective and widely used building materials.”

Nevertheless, unprotected concrete does degrade “because of intrinsic flaws in the material and the impact of harsh climatic variables.” This degradation reduces the life span of concrete structures by 50 to 70 percent! Dealing with this problem creates significant financial losses. “It is estimated that corrosion-related losses account for approximately 2% to 4% of the global GDP.” In China, repairs for failing concrete can cost up to $310 billion annually, while in Europe “more than 50% of Europe’s annual construction budget is allocated to the renovation of aging concrete structures.”

Concrete Lasts Longer with Protection

Concrete coating technology is a key measure that enhances the durability of concrete structures. — From the journal Coatings

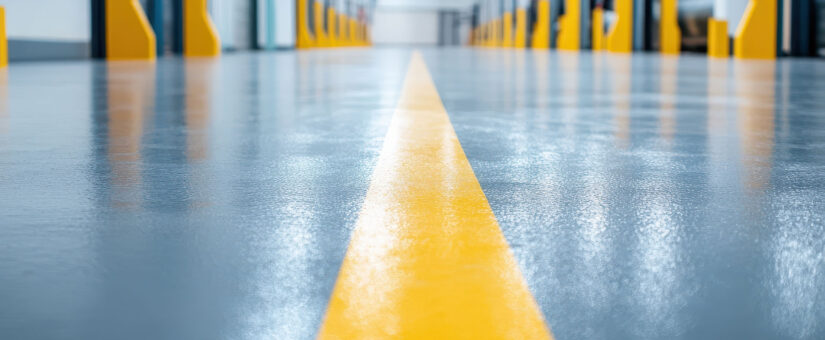

After discussing the problems with concrete maintenance faced by facilities and institutions around the world, the scientists responsible for the Coatings article also pointed to solutions. One of the highlighted answers for preventing concrete degradation was the application of “surface-film-forming coatings”, just like those offered by California Custom Coatings. “Surface-film-forming coatings can create a dense barrier, …making [concrete] suitable for humid and high-chloride environments.” The researchers also stated that “surface coatings form a physical barrier that can effectively prevent the penetration of chloride [salt] ions, moisture, and other corrosive media.”

There are many ways besides applying concrete coatings to “harden” concrete. These include using superior materials in the cement and applying certain time-consuming or labor-intensive installation techniques. This is therefore one of the primary advantages of post-installation or renovation surface coatings. As the authors of the Coatings article explained, “surface coating technology has gradually become a key focus of research and has been applied for concrete corrosion prevention due to its convenience, low cost, and wide applicability.” [italics ours]

California Custom Coatings will return to this excellent article and its conclusions about surface coatings for concrete in a future blog post. In the meantime, you can find out more about how we can protect your concrete from early degradation by calling us in Northern California at 916-612-2399 or contacting us online. California Custom Coatings is proud to provide convenience and low cost for many concrete applications!

* Zhao, H.; Wang, Q.; Shang, R.; Li, S. Development, Challenges, and Applications of Concrete Coating Technology: Exploring Paths to Enhance Durability and Standardization. Coatings 2025, 15, 409.

- On July 24, 2025